Motocross, enduro racing and FMX (the freestyle version of motocross) are some of the most dynamic wheeled and action sports around today. They place the motorcycle in situations which far exceed the performance capabilities of their road-going counterparts. Modern-day ‘Evel Knievels’, such as the legendary stuntman, Travis Pastrana, and his Nitro Circus counterparts, regularly amaze their audiences, literally defying death with their feats. In replicating Knievel’s iconic jumps over multiple cars and buses, and the odd Caesar’s palace fountain or two, failure is not an option, be it the rider’s nerve or the bike structure on impact.

Find out more about the CAE tools we used at MSC Apex Overview.

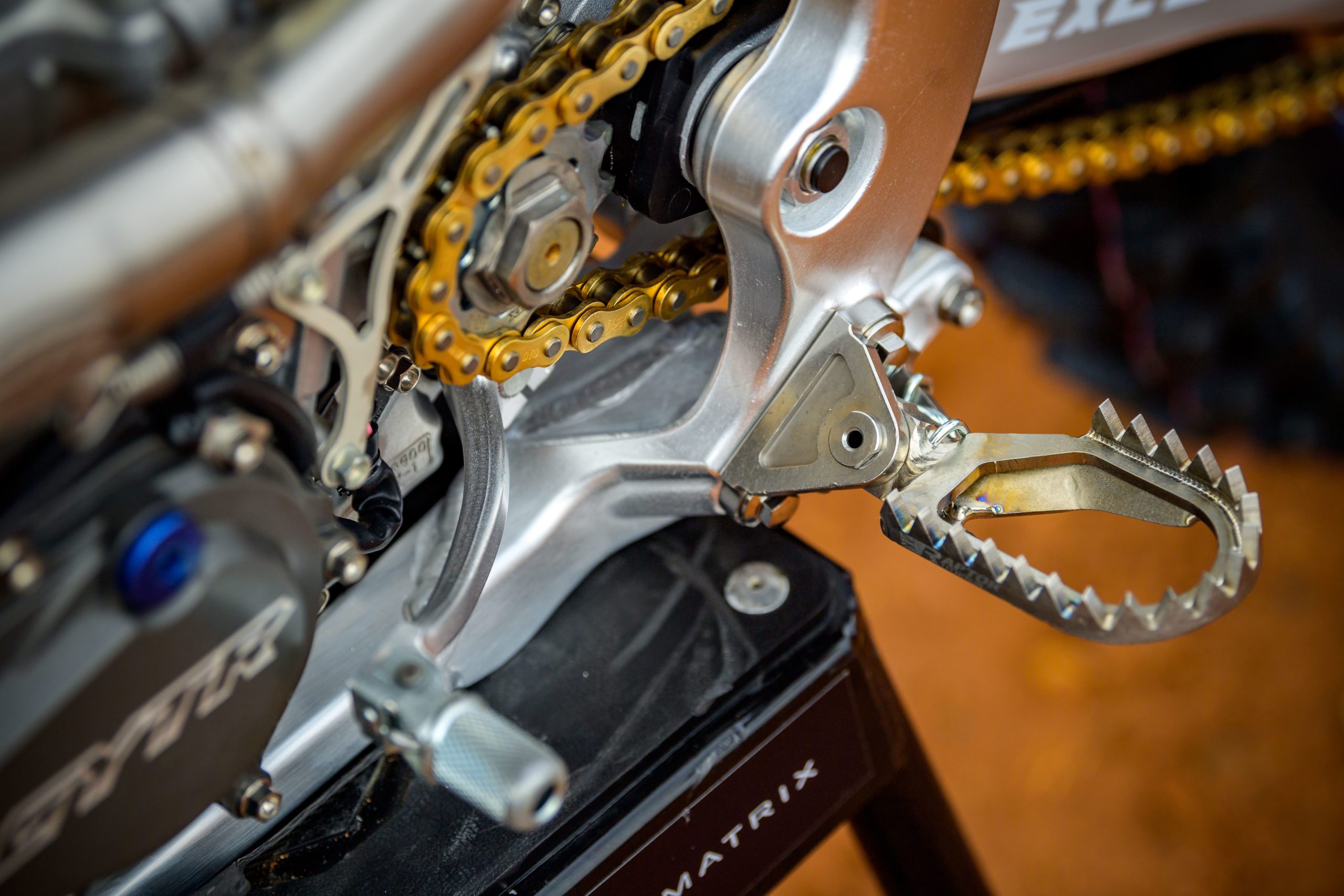

One company crucial to all of this, Raptor Titanium, is based out of Lancashire, in the UK. Their titanium foot-pegs have gained a worldwide reputation through the performance that Pastrana and fellow extreme athletes require. Raptor had their beginnings in the aerospace industry, supporting the welded manufacture of titanium fan blades used in some of the world’s most powerful jet engines, but moved over to foot-peg manufacture through a general love of all things motorcycle, and some pretty fancy-schmanshy welding technology (all top secret by the way).

Now with over 20 years of top-notch manufacture, they support numerous elite professional teams (think KTM Red Bull, Kawasaki RT, and Rockstar Husqvarna to name a few) along with title-winning riders, such as Pastrana, Clement Desalle, and Tony Cairoli (all multiple X-games, GP, and world title holders in their own right).

Project Motivation

Historically, Raptor have used significant ‘in-field’ testing to develop their aggressive designs. This has been based around rider feedback, coupled with a smattering of practical lab testing involving dropped masses to replicate the impact loads seen during riding. Pair this response with the multi-year warranty that Raptor issue with every set of pegs means that a breakage is painful at the very least, and catastrophic at worst.

Over the years, development has been a slow, incremental process, based on subtle changes to design, manufacture and material choice. With a growing customer base, you’ve got market competition firmly biting at your heels, whether it be plain design infringement, or lower cost, inferior manufacture.

We at Evotech CAE were introduced to Raptor through an industry-focused development initiative to upskill companies in the light of the new normal for UK manufacturing that Brexit, COVID-19 and other market factors (such as raw material usage and supplier lead times) have brought. Initial conversations were based on a desire to reduce development time and improve product performance through digital technologies.

With our background in advanced FEA, this was a perfect fit for our skill set. Many readers will see this an obvious step, but a carefully considered simulation strategy could make a massive difference to Raptor, both in simply better understanding their product (and warranty) and allowing future optimisation.

Optical Scanning

The first stage of this strategy was to obtain reliable 3D geometry of the foot-peg form. The peg assembly was made up of a series of CNC’d titanium parts, with press formed ti plate, all welded together using Raptor’s ‘secret sauce’. Sure, CAD data existed of each of the component parts, but a fully welded CAD model (with the organic intricacies of the smoothed weld geometry) simply didn’t. This was when scanning and reverse engineering came in.

Through an existing Raptor relationship with GOM UK, we were able to generate the necessary STL data to give us a starting point for reverse engineering. It’s at this point that I have to say I learnt a huge amount about the scanning process, and the ability to generate usable CAD for down-stream processing. I would say I was naïve in thinking that you just point the scanner, generate the point cloud, then hey-presto, there’s your CAD. It’s not quite as simple as that, so let me explain…

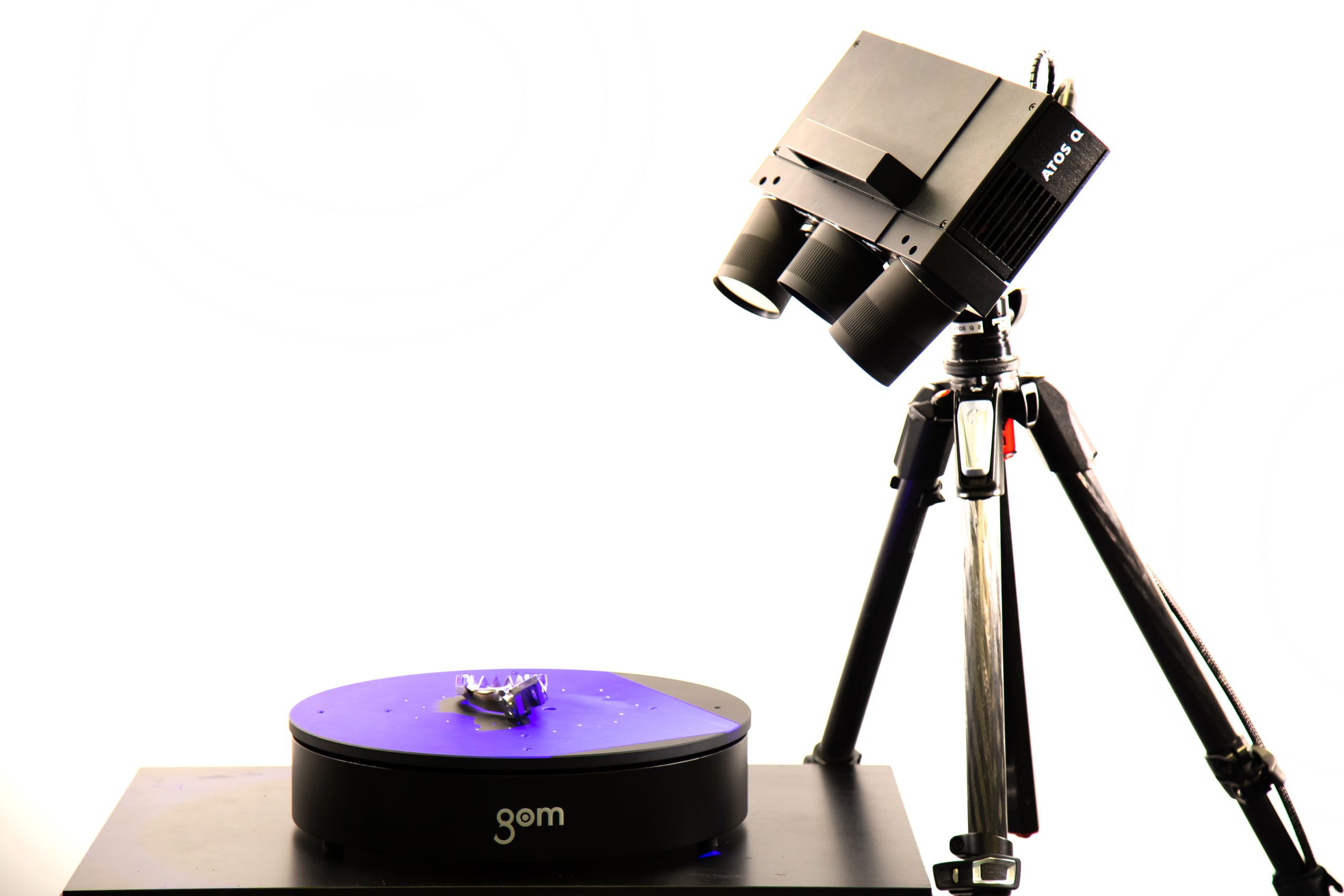

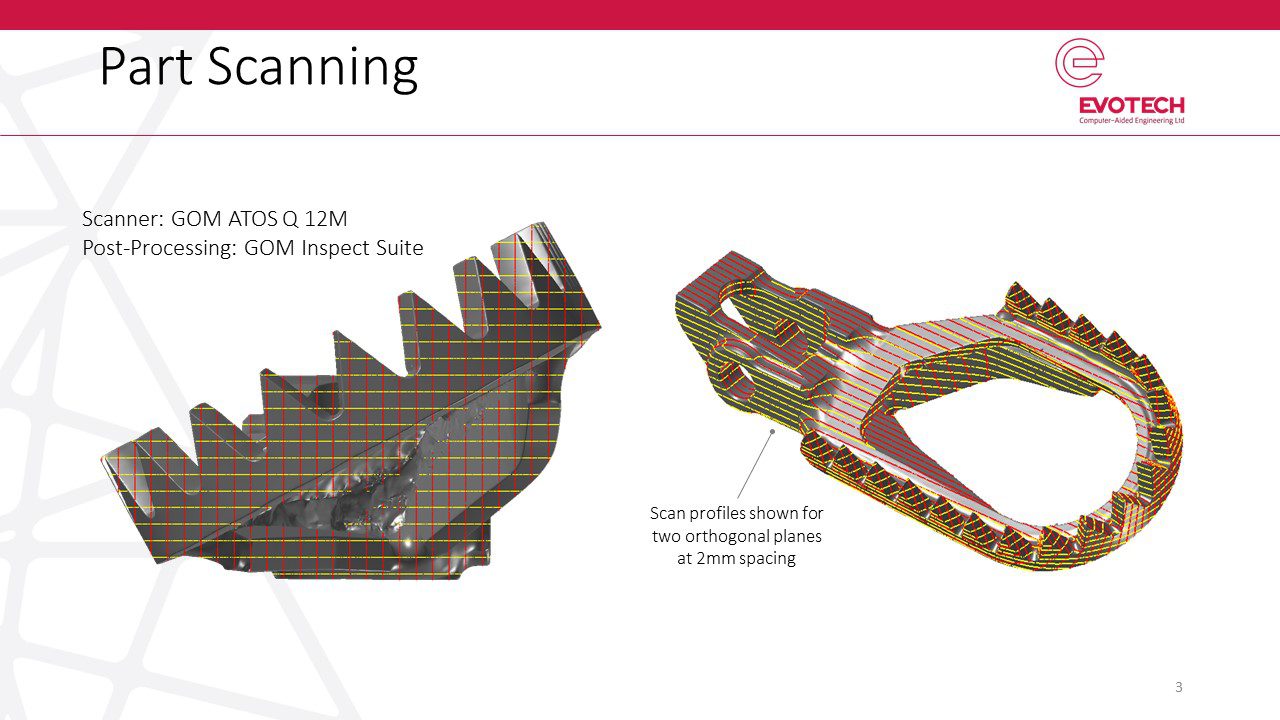

GOM UK utilised their latest ATOS Q 12M digitizing system, which utilises ‘blue light technology fringe projection’ and two stereo cameras, to capture high quality point cloud data of the part. An automated rotation table was used to assist the positioning of the part in different orientations for the cameras – like how you might orientate the part to your eyes to observe the different surfaces. The supporting software, GOM Inspect Suite, brought the data together, with feedback to the user on the data captured.

There were a few issues with ‘line of sight’ where the cameras simply couldn’t reach some of the undercuts where parts came together. Sure, existing 3D geometry would have given us a ‘heads up’ here, but instead we used the geometry processing capabilities of the GOM Inspect Suite software to fill in the gaps, and generate planar sections required to rebuild the clean geometry.

Find out more about the CAE tools we used at MSC Apex Overview.

Side note on Geometry Manipulation…

The STL output from a scan (and the post-processed data) is made up of thousands or millions of points, all connected through a huge set of flat triangular faces which enclose a water-tight volume. If you’re looking at something fairly regular, with lots of flat faces, then the ‘facet body’ (as it’s known colloquially) will do. However, if you’ve got lots of features (radii, double-curved surfaces etc.) then a better definition is required.

Non-Uniform Rational B-Spline (NURBS) is a powerful mathematical description of geometry, to yield a far cleaner form than its STL facet body ‘little brother’. If you want any kind of smooth geometry that can be easily manipulated (add/removing features, extending solid faces), not to mention FEA-meshed, then NURBS geometry is a must-have. Fortunately, there have been many advances in this kind of geometry definition which make this 1) a reality and 2) accessible in a form that doesn’t take forever and break the bank at the same time. Drum roll for MSC Apex please…

Many of you who follow my LinkedIn activity will have heard me extoling the virtues of MSC Apex (yes, cringe, I am ‘The Apex Guy’!). Without trying to turn this into a veiled advert for the technology, if you’re using any kind of production FEA, in pretty much any industry, then you need to be looking at what Apex can do for you. It’ll save you time and resources, allow for better product development, and all in an environment that is both nice (yes, nice!) and cost-effective for organisations of all sizes. There, sales pitch over!

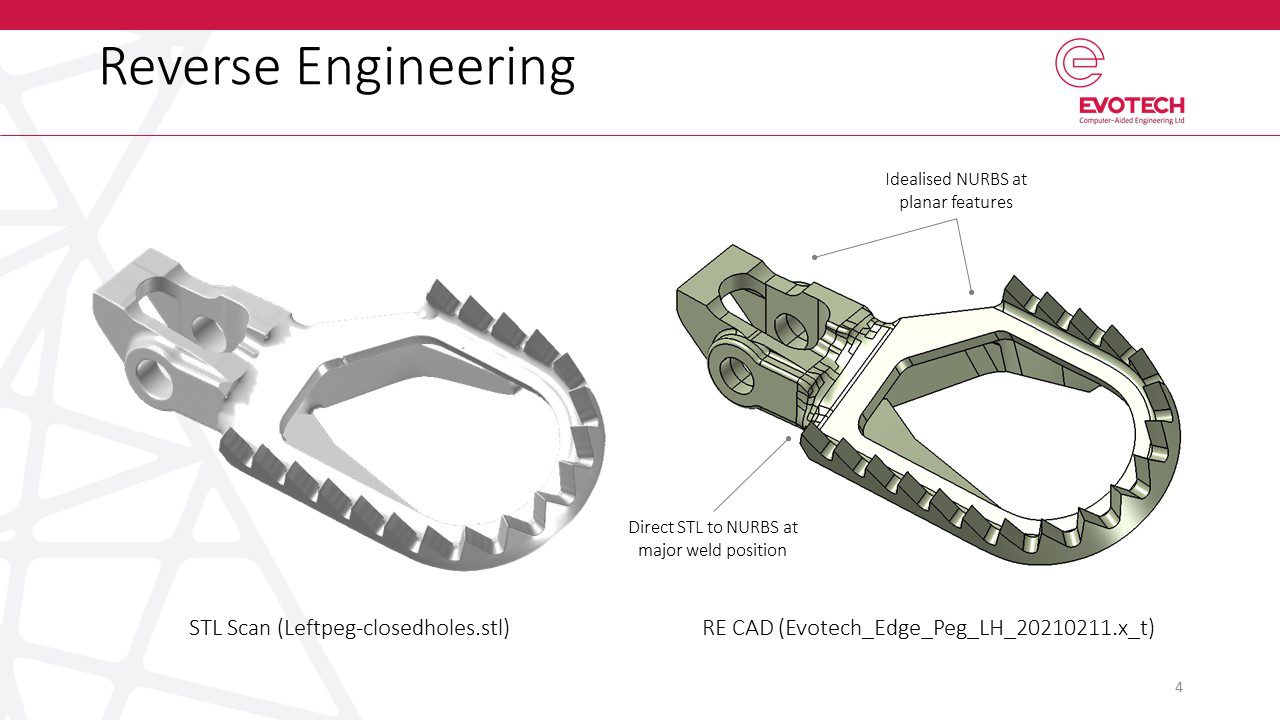

Reverse Engineering

MSC Apex uses a state-of-the-art Parasolid geometry kernel for FEA model development. Fundamental to this is the ability to create and manipulate geometry in many forms. There are tools in Apex which easily match or surpass the most powerful CAD software on the market today, and all within a CAE/FEA platform. One of these workflows is the ability to reverse engineer legacy FEA mesh data into a form that can be redefined for a new model, whether that’s to add additional structure, or to look at different analysis strategies, such as sub-modeling. A by-product of this ‘mesh to CAD’ workflow, is the ability to reverse engineer imported STL scan data into NURBS geometry.

We used these tools to re-build the geometry from the STL point cloud and the section curves that GOM Inspect Suite generated. The section curves were used as construction geometry for the standard NURBS primitives (planes, cylinders, spheres) for the machined regions, where it was easier to understand the design intent or shape in the structure. The more organic regions (historically more difficult to handle, especially at the weld interfaces), were represented with double-curved patches which were lofted using shape constraints into the machined region interfaces.

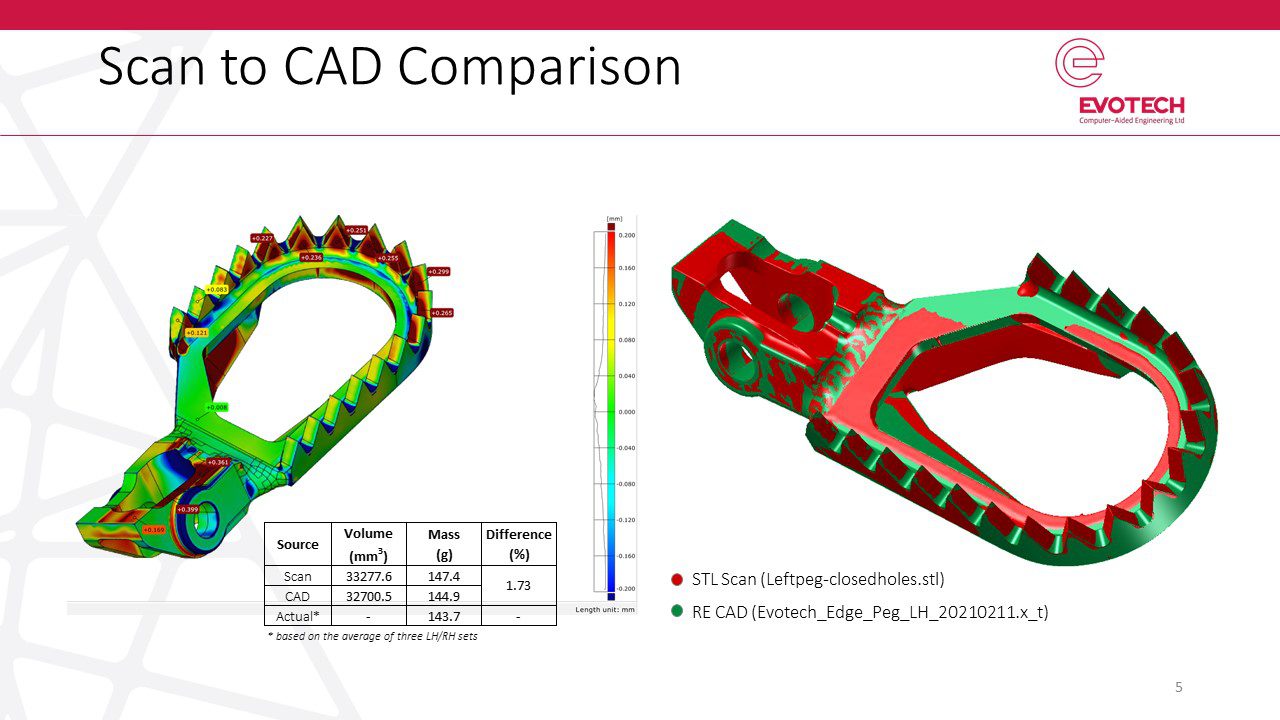

Once the geometry has been recreated, we were able to use GOM Inspect Suite to compare with the original STL definition, both in terms of visual overlay and enclosed volume. The overlay showed a high degree of accuracy, especially at previously critical structural features. The calculated volume of the NURBS CAD was within 1.7% of the original STL form. We also checked the left/right comparison for a pair of pegs to understand any manufacturing variance, and its impact on the down-stream analysis. Any differences were shown to be tiny, and well within the ‘noise’ of the resultant FEA. A side benefit of the CAD geometry creation meant that Raptor also had reliable assembly CAD for their CAM and inspection processes.

Side note on ‘Mesh to CAD’ for Generative Design/Topology Optimisation…

One area where this STL/facet body to NURBS workflow is gaining traction is in the development of ‘clean’ geometry following a Generative Design/Topology Optimisation run. Historically, this optimisation workflow would have meant lots of semi-manual post-processing (and potential inaccuracy) in developing geometry from a mesh (I’ve suffered this pain many times – it’s not pretty!). These newer Parasolid-based ‘Mesh to CAD’ techniques mean that the smooth output from ‘level set’-type optimisation runs can be converted to NURBS CAD in a fraction of the time taken in the past.

FE Analysis

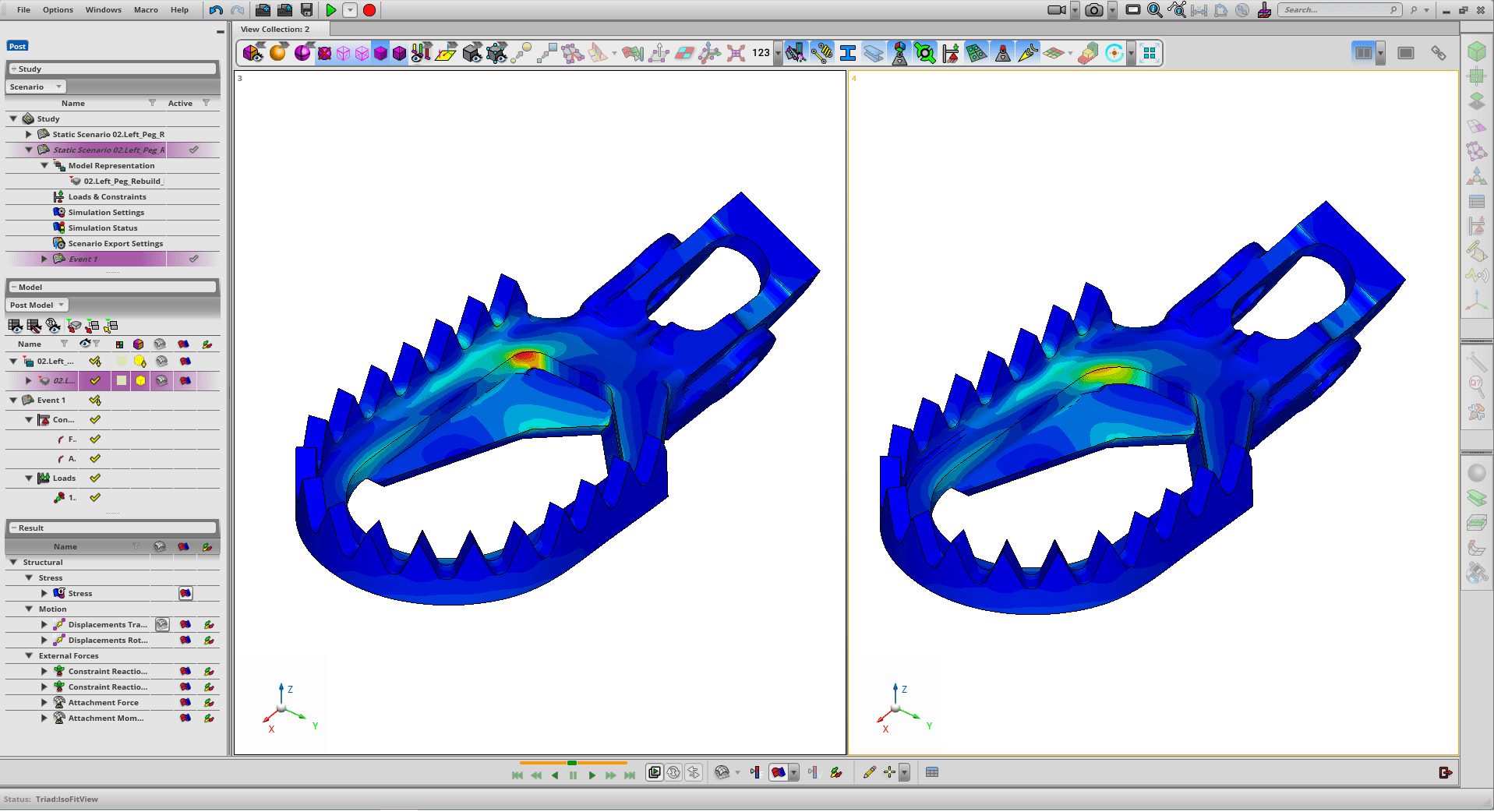

Once generated, the NURBS geometry could be 3D meshed (using 10-noded Tet elements), with the appropriate automatic feature controls on fillets, faces, hole washers and cylinders. An iterative mesh convergence study was performed using the embedded Apex ‘generative update’ tools to give the appropriate balance between converged feature-based stresses and model size. Had the resulting model been too cumbersome, then we could have adopted a hybrid solid meshing approach using hex elements, but this was not the case.

We applied unit static and fatigue loading to determine the load to failure in key directions from the material allowable strength. Once determined, this was assessed both in terms of non-linearity and sensitivity to load direction. Given that we had access to NURBS geometry, we were able to show the impact of design changes (such as thinning the discrete plates or changing weld sizes) from a mass and strength perspective.

The Future

While the FEA aspects of this project were not particularly ground-breaking, the ‘part to CAD to FEA’ workflow was something pretty new to us. The ability to generate clean geometry in a timely manner, then witness the response, gives at least an order of magnitude of improvement in Raptor’s development process. And all using contemporary software that eased the whole process and made it commercially viable.

So, what does this mean to Raptor? Well, they have a much better idea of their product’s performance, where the manufacturing and performance sensitivities lie, and what they can do with their next generation of foot-pegs, whether it’s looking at new bespoke geometries, manufacturing methods (including AM) or new markets. Reverse engineering has been around for a while, but the ability to use the latest optical scanning techniques, coupled with state of the art ‘mesh to CAD’ and FEA model generation, gives companies both large and small the edge they need in designing in the products of tomorrow.

As I conclude this, I’ve noticed that 19 buses have parked up outside my house, blocked the road, and I need to get out to pick my son, Sol, up from school. Where’s Travis Pastrana’s bike when you need it…!

Find out more about the CAE tools we used at MSC Apex Overview.